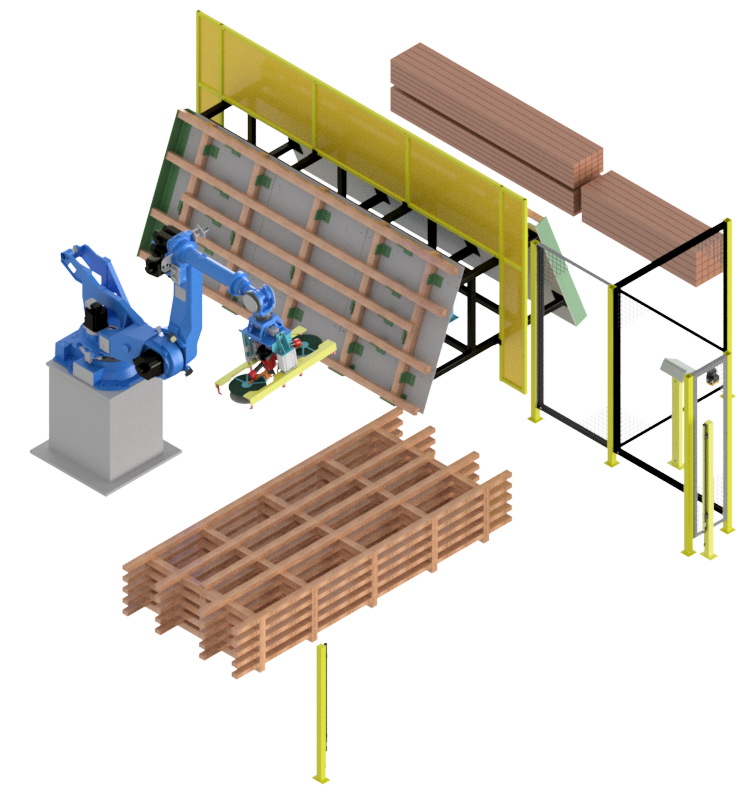

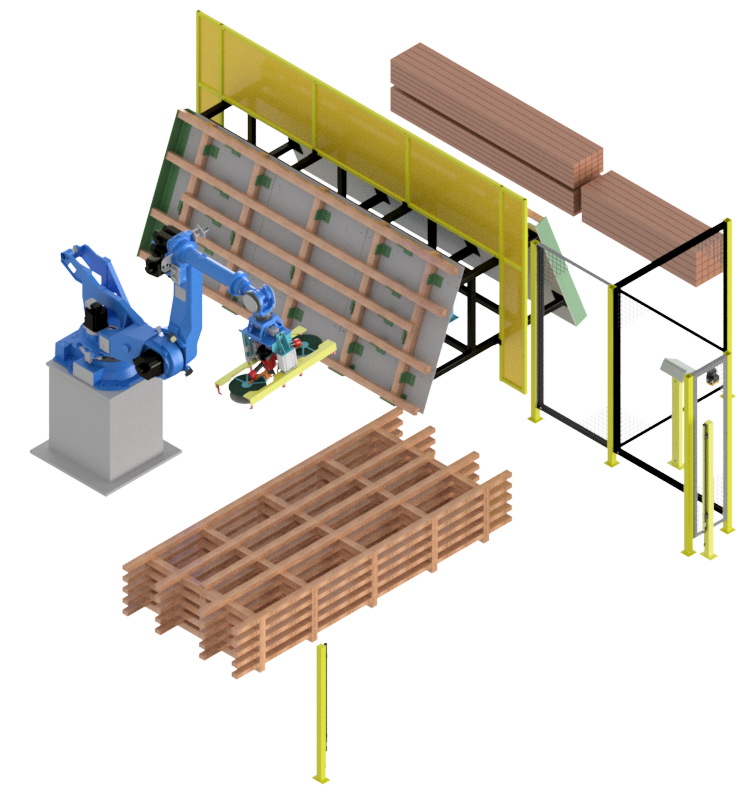

Despite the recent COVID-19 breakout, just over six months later, this system was successfully installed and commissioned in the middle of 2020. The robotic and automated system comprised of:

- An intelligent Nachi SRA210 handling robot equipped with a dual-purpose custom-made gripper for automated nailing and pick-and-place/stacking process,

- A turntable mounted with two template jigs, allowing one assembled skid to be nailed on one side whilst an operator can safely load and assemble the timber bearers on the other side,

- Complete safety system consisting of safety fences, light curtain, floor scanner and a safely isolated start/stop station for the operator.

Robotic Skid Nailing System Layout

Robotic Skid Nailing System Layout

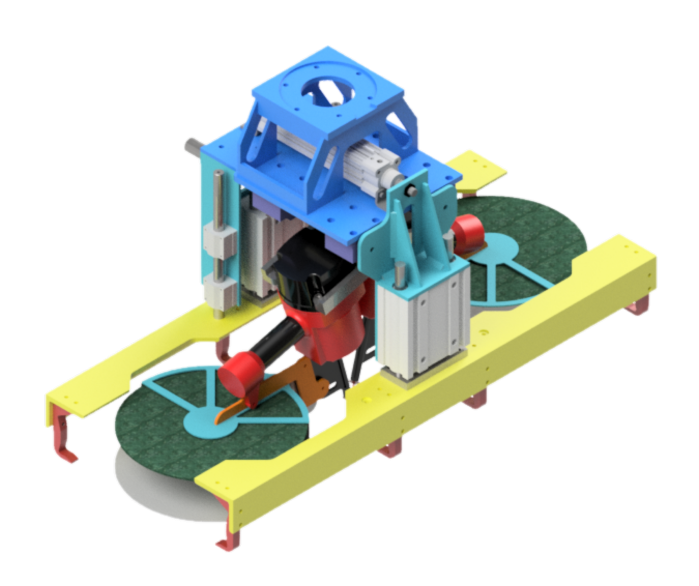

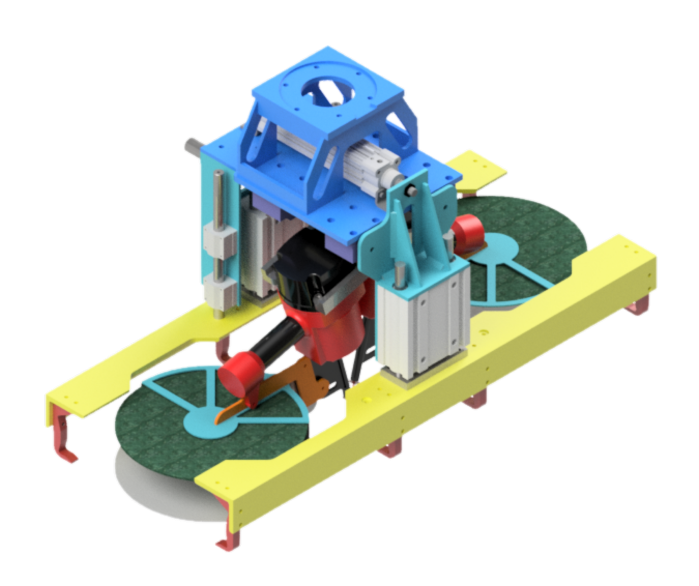

The robotic gripper/end-effector was purposely designed and made to have two nail guns mounted on it for two simultaneous nailing onto the intersecting timber bearers. In addition, a gripping mechanism to allow the lifting and stacking after the nailing process is done was also implemented in the same gripper.

Dual-purpose, custom-built Robotic Gripper

Dual-purpose, custom-built Robotic Gripper

Overall, the client was extremely impressed at the outcome of this project. The automated system has achieved the expected performance and was completed on schedule, despite the global pandemic we are currently in.

For ordering and more information on robotic and automated systems, please do not hesitate to contact us! We are passionate in helping your business grow and realise its true potential!

Stay tuned for more news and information regarding our robotic systems!

Follow us on LinkedIn and Facebook for more information and updates regarding our robotic systems!