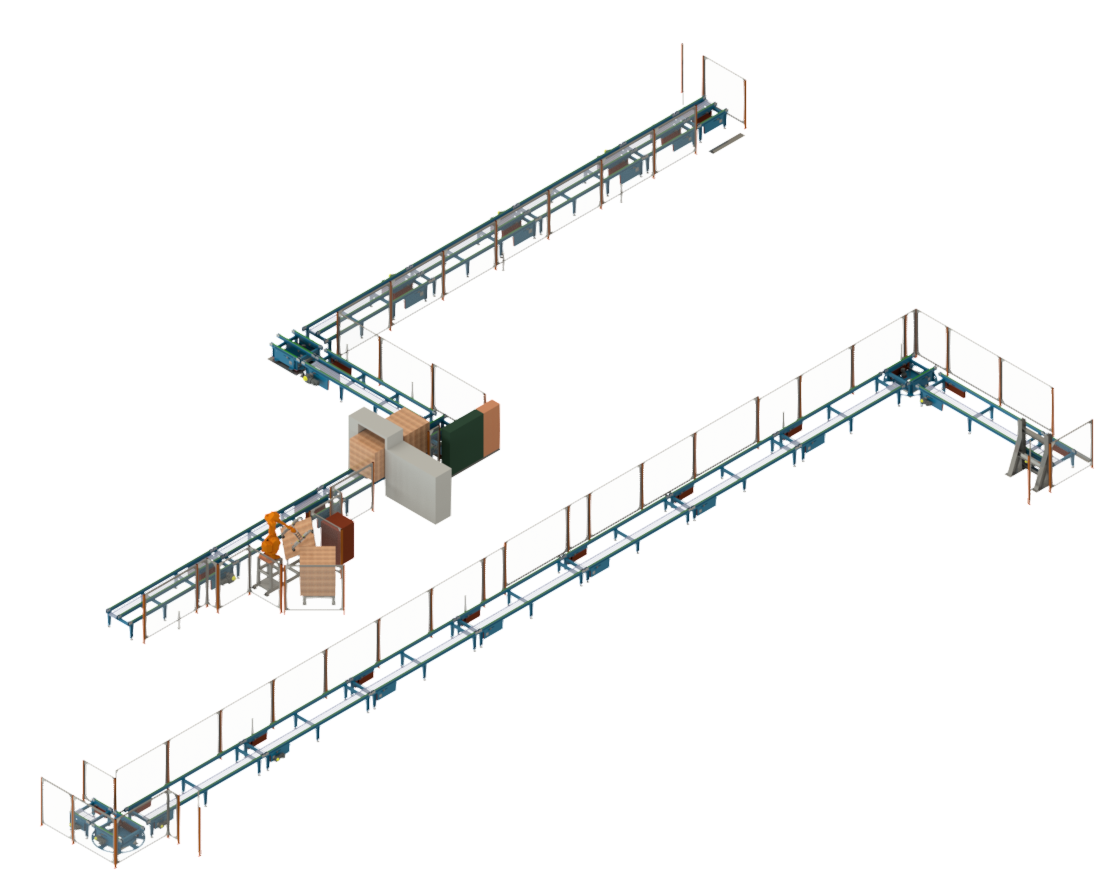

R&E Engineering successfully designed, supplied and installed 90 metres of pallet chain conveyors along with a robotic handling system for a client in Western Australia. However, the real benefits of the system do not just lie in its size, but also in its numerous advantages and capabilities that will be specified below.

THE PURPOSE

The ultimate purpose of the system is to allow the operator to load empty palletised boxes onto the infeed conveying system and unload fully loaded, sealed & secured palletised boxes from the outfeed conveying system.

THE OPERATION

The procedures in operating the pallet chain conveying system involves the operator/forklift driver to load empty palletised boxes one by one onto the infeed conveyor from a loading point, which will travel up to the end of the infeed conveyor line and stops just before entering the client’s existing system. The empty boxes will accumulate backwards from the end of the infeed conveying system as the forklift driver loads more onto the infeed conveyor line. Then, when requested by the existing system, the infeed conveyor transfers one empty palletised box at a time while indexing the rest of the accumulation forward to fill in the empty space.

In the existing system, these boxes are filled with products, which will then be transferred onto the outfeed conveying system one by one. The operator can load empty palletised boxes at any given time onto the infeed conveyor providing there is space for accumulation.

Upon receiving a fully loaded palletised box, the first outfeed conveyor then be transfers it into the robot cell and stops for the robot to scan the position and orientation of the box, pick up a lid for it and puts it on accurately. Then from the robot cell, the fully loaded palletised box travels onto the next outfeed conveyor, where it will be double strapped by an automatic strapper. It then resumes its travel up to the forklift pick up point and accumulate backwards. At any moment, the forklift can unload the full box one by one, provided that there is a full box ready for unload. When one full box is removed from the system, the whole line of accumulated boxes indexes by one to fill in the empty space. Then the process just repeats.

THE BENEFITS

R&E Engineering only provides cost-effective robotic and engineering solutions that will result in significant improvements to the existing production system. The system has numerous benefits as follows;

- Increased Production Output: Since the installation of our systems, our client has reported an increased output of more than 30 tonnes per day.

- Effortless Operation: As the system provides accumulation capability in both loading and unloading, a single operator can run the entire system with no trouble and without rushing from point to point. To the operator, this means improved productivity while reducing their stress.

- Operational Safety & Security: The system is enclosed within the perimeter of our safety fences (to the Australian & our client’s safety standards) with keyed gate access to prevent unauthorised access. The operator will always be out of harm’s way when operating the system. We have also installed ten safety Emergency Stops at convenient locations to ensure that an E-Stop is always within reasonable reach of the operator.

- Improved Workers’ Health & Safety: Our client previously had workers to manually put on the box lid. The problem is that the product is highly toxic. Even though the workers wore a full protection suit, the risk is still there. The robot handling system replaces the manual box lid placing and therefore eliminates the risk altogether.

- Informative Human-to-Machine Interface: The operator can easily identify if there is an error occurring within the system at any point in time and location just by a quick glance into the control panel screen. Indicators and error messages will appear on the screen to signify where on the system an attention is required.

- Operation Flexibility: During any point in time when the system needs to be stopped, the operator can do so very quickly with a single push of a button. The infeed and outfeed system work independently to each other and therefore can be run on their own. When the system is restarted, it will be able to resume its operation prior to being stopped. Or if there is any change within the system while it’s stopped, the system will be able to recognise the changes and adjust itself to resume operation from its current situation when restarted.

- Full System Integration: Our client can still use their existing system as they are integrated into the new system. For example, the strapper is controllable from our HMI control panel. We have also added an automatic indexed double strapping feature to better secure the fully loaded pallets on our outfeed conveyor. This is done by setting up communication between our control system to the client’s existing equipment to enable complex coordinated movements.

- Precise Robotic Handling: The robotic system can reproduce the exact same quality results every single time due to precise programmed positioning. This means that the sealed product will always come out of the robot cell in the same manner, provided that there is no irregularity prior to coming into the cell. Though, irregularities to a certain extent, is acceptable due to the sensor on the robotic gripper which automatically calculates required positioning adjustments for the robot and executes it.

- Low Maintenance Requirements: The system maintenance can be done once every three months and are mainly lubrication, which has very minimal requirements in terms of time, labour and operation interruption.

For more information on robotic and automated systems, please do not hesitate to contact us! We are passionate in helping your business grow and realise its true potential!

Stay tuned for more news and information regarding our robotic systems!

Follow us on LinkedIn and Facebook for more information and updates regarding our robotic systems!