Versatile Robotic Gripper

To compliment our robotic systems, R&E Engineering offers various types of Robotic Gripper that can handle a large variety of products. Our robotic grippers are designed to suit the type of product handling application in the most efficient way. Whether it is a bulky and rigid product or a small and fragile product, we can design the robotic gripper to cater for the products.

We have extensive experience in developing robotic grippers. Different processes can be combined into a single robotic gripper. This, in turn, results in a more compact yet versatile robotic gripper. There are a few ways of powering these grippers, the most common methods are through pneumatic (ie. air or vacuum) and electrical (ie. motor driven or electromagnet).

If you are interested or have any questions in regards to this product, do not hesitate to contact us. Our friendly sales representatives will be happy to chat with you!

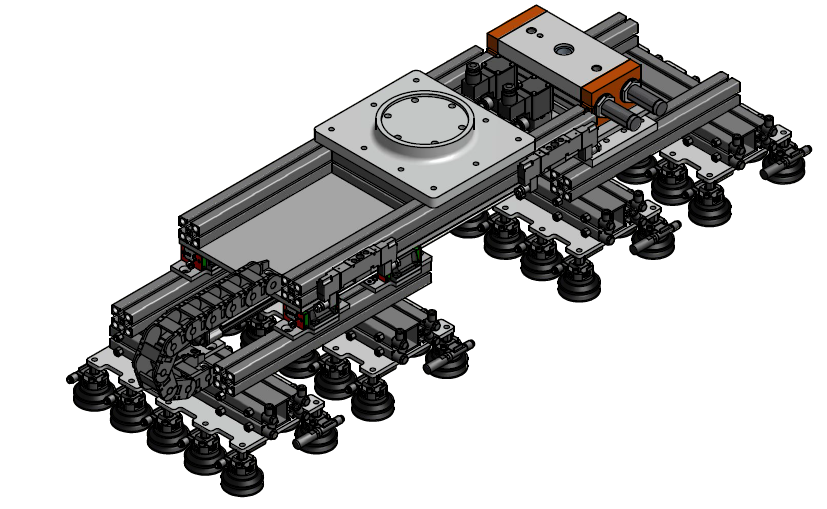

Vacuum Gripper

This gripper utilises vacuum or suction force to lift objects. Ideal for handling boxed or solid products. Different functions can be installed into this gripper, such as compaction or product rearrangements function. This allows the robot to pick multiple products and compact them or arrange them into a pattern before placing them onto a pallet.

Stabilised Palletising

Different arrangement patterns can be achieved to improve the stability of the palletised products. As the robot puts more products onto the pallet, the height of it increases, introducing more instability. These functions serve to reduce these instability until the pallet is ready for wrapping or strapping. This means, palletising will be more efficient and safer. With a range of different shape vacuum heads available and the flexibility to change the number of heads the gripper can be customised to suit your products specific needs.

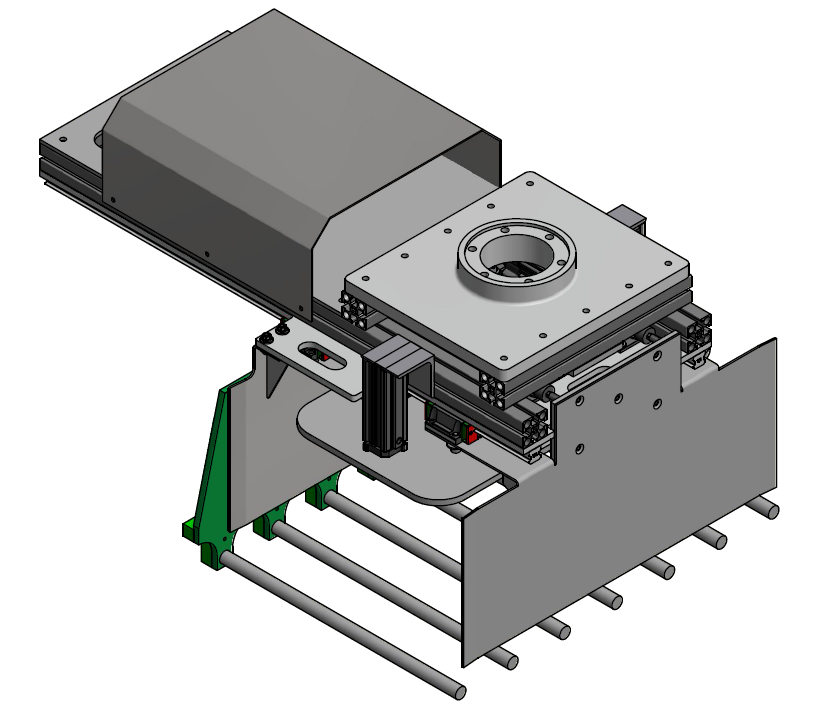

Fork Gripper

The fork gripper has prongs to slide under a product and uses it as a support for carrying. This type of gripper is perfect for handling bagged products. The prongs enable the gripper to go in between roller conveyors to obtain the product and provides equal weight distribution across the product. This way the product retains its form while being handled.

Secured Positioning & Accuracy

The gripper can be equipped with more functions to provide stability while carrying. This is usually required when operating at higher speed settings. Some functions that can be installed include a top pressure plate and a side shift plate. This ensures that the product stays secured in position while the robot transfers it onto the pallet. Additionally, as this improves the consistency of the product shape and position, it also improves accuracy of palletising.

Careful Handling

Through the use of the retractable forks, products are laid onto pallet instead of dropped to ensure no damage or tearing to the bag. Ideal for thinly bagged products that are susceptible to tears or splitting.

Complete Integration

Custom pick-up roller conveyors are available that can be adapted to suit any existing production lines. This is to reduce any interruption to the production line.