Various Accessories to Complete Your Robotic Panting System

Accessories provided by CMA Robotics will ensure a complete and smooth operation for your painting system. Whilst some of these accessories are essential, some are optional depending on what your painting criteria. Having said that, custom made accessories can also be provided at your request.

For more information, contact us now!

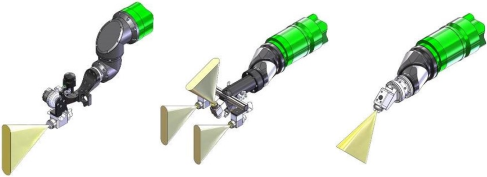

Spray Painting Gun-Heads and Support

CMA Robotics has designed an adaptable gun support to be attached at the end of the robot’s wrist. It is suitable for most major gun-heads brand. This support allows one or multiple gun-head attachment. Giving flexible option to save paint usage and more painting area covered, leading to faster cycle time. Customised support will also be design when necessary to ensure any gun-head can be mounted firmly.

Self-Cleaning Station and Robot Cover

A cleaning station can be provided to clean the spray-gun nozzle. This routine is added onto the robot program to guarantee high quality consistency of paint in every painting cycle. Made out of synthetic bristles to make sure the nozzle to be clean without damaging it.

Each robot from CMA Robotics will come with a cellulose-based robot cover. Protecting important part of the robot from any paint, it is designed to be flexible omitting any interference to the robot’s movement.

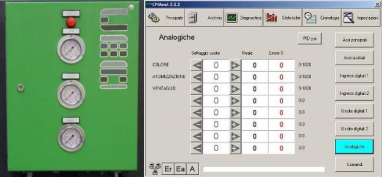

Automatic Control of Spray Painting Parameters

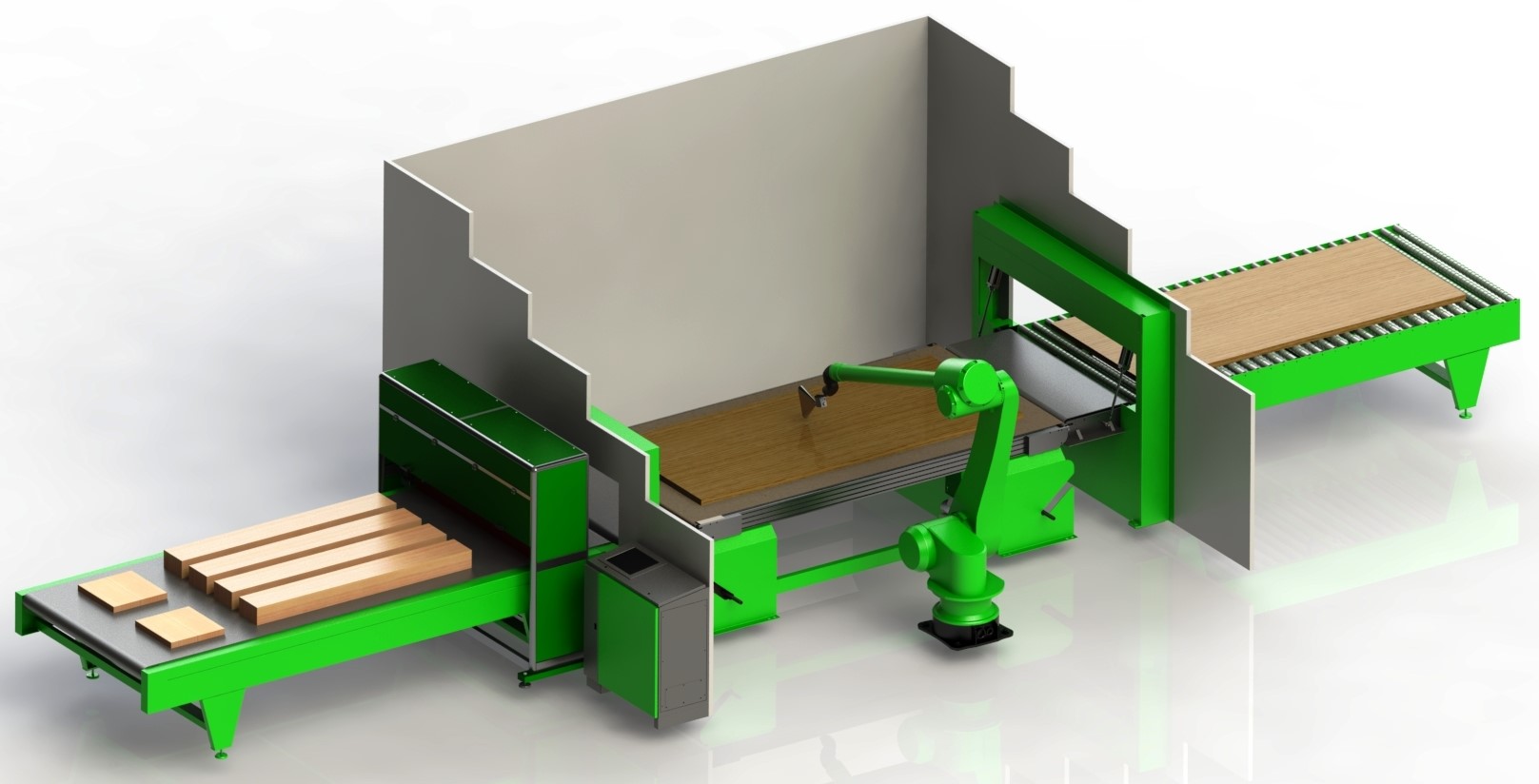

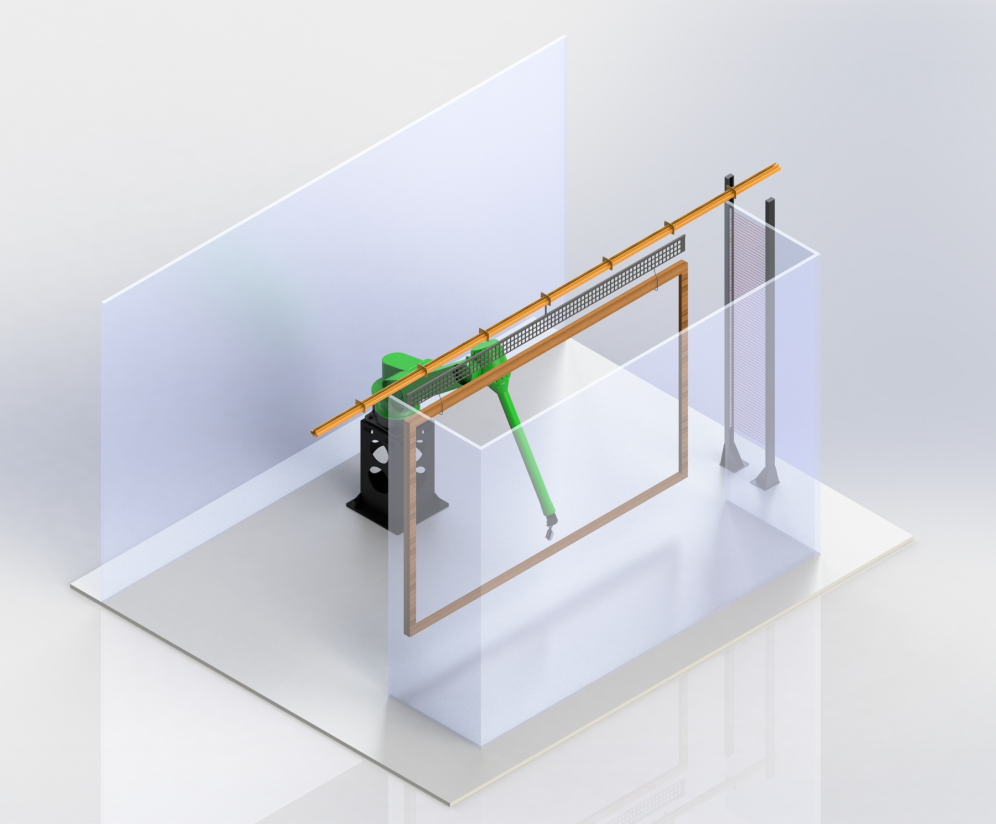

Self-generated Program via a Vision System

CMA Robotics offers state of the art solution for complex shape workpieces. Items can be arranged horizontally on a conveyor or hanging vertically using an overhead conveyor to be painted by the robot. Before the painting station, they will first pass through a scanner which maps the item in a form of data points. These are then transmitted to a personal computer which has the software to create a program based on these points. From here instructions are then sent to the robot to begin the spray painting process. Each item can differ in sizes and shapes, the program will automatically adapt once a different item is scanned.

A video showing this application can be seen here.

Horizontal Painting

Vertical Painting

We can also work with various brands of robots, such as FANUC, YASKAWA, ABB, KAWASAKI, PANASONIC, MOTOMAN, OTC, NACHI, DENSO, KUKA, MITSUBISHI, EPSON, STAUBLI, FOXCONN, COMAU, OMRON, and UNIVERSAL Robots