Purposely Designed for Optimum Efficiency and High Precision Quality

CMA Robotics offers accessories that can be integrated to their robot granting them more flexibility and range. The robot or the workpiece can be moved with these positioners. Having either one or both depends heavily on the required painting criteria. Customisation for either positioners are available to suit specific applications.

For more information, contact us now!

Robot Positioners

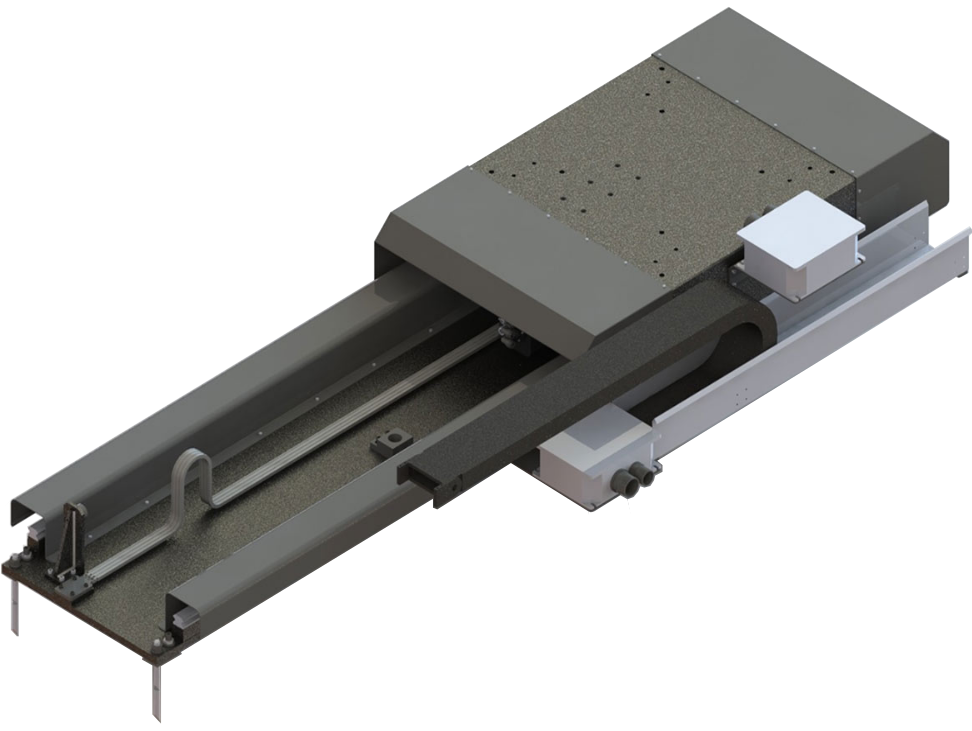

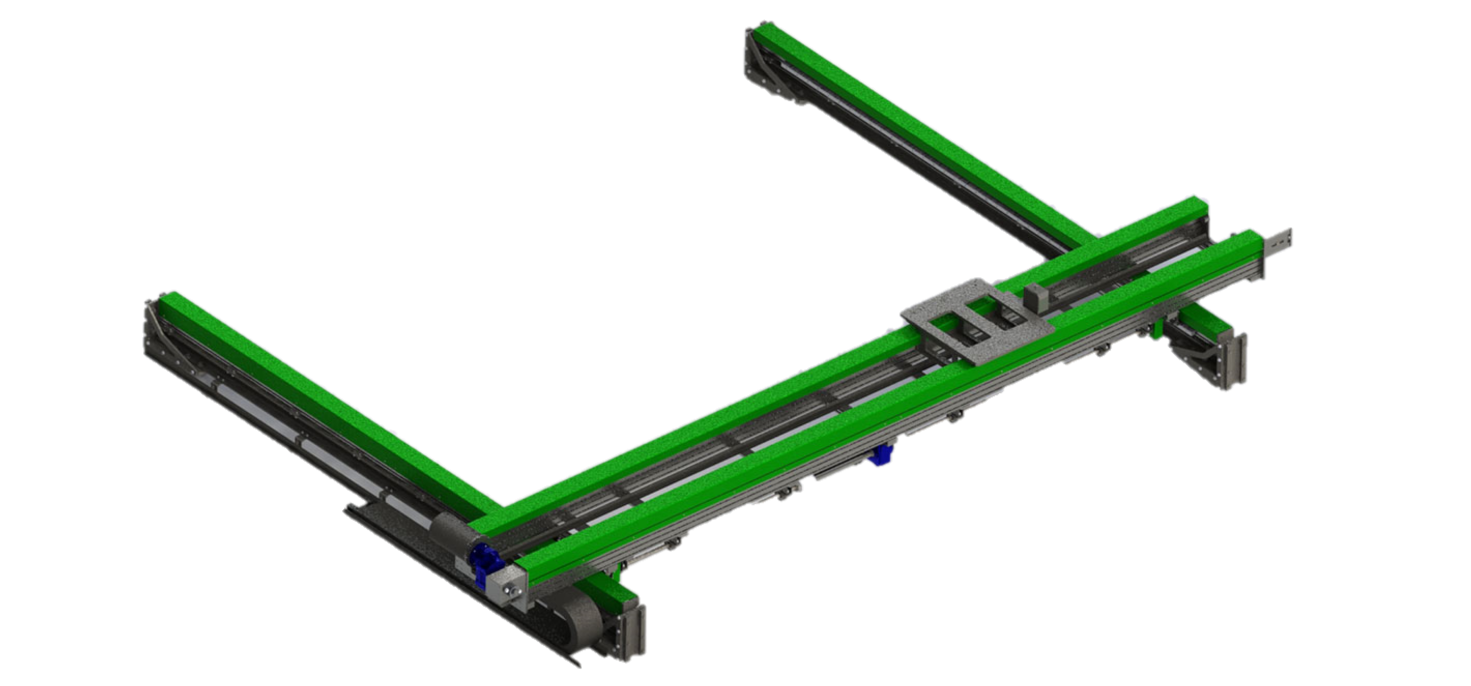

These are essentially additional axes (7th, 8th, etc.) to the robot allowing it to traverse in a 2D-plane extending its operating range. It is usually comprise of one or more linear rails depending on the required spray painting area. They can be installed on the floor or the ceiling (gantry-type) to paint workpieces at a 360° with ease. Most of these rails are powered electrically, however, pneumatic-powered linear rails are also available for smaller movement/strokes. With these linear units, work-pieces can be setup on different stations along the robot’s path, so while the robot is painting an item, the next item can be prepared simultaneously.

Small stroke linear axis

One linear axis

Two linear axes

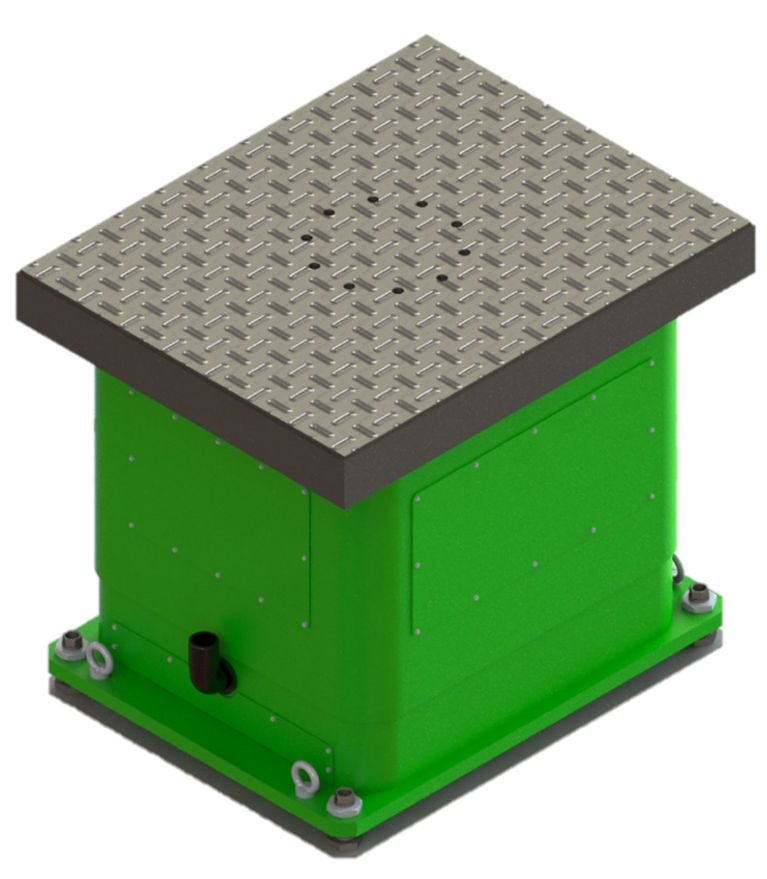

Fixed (Non-rotating)

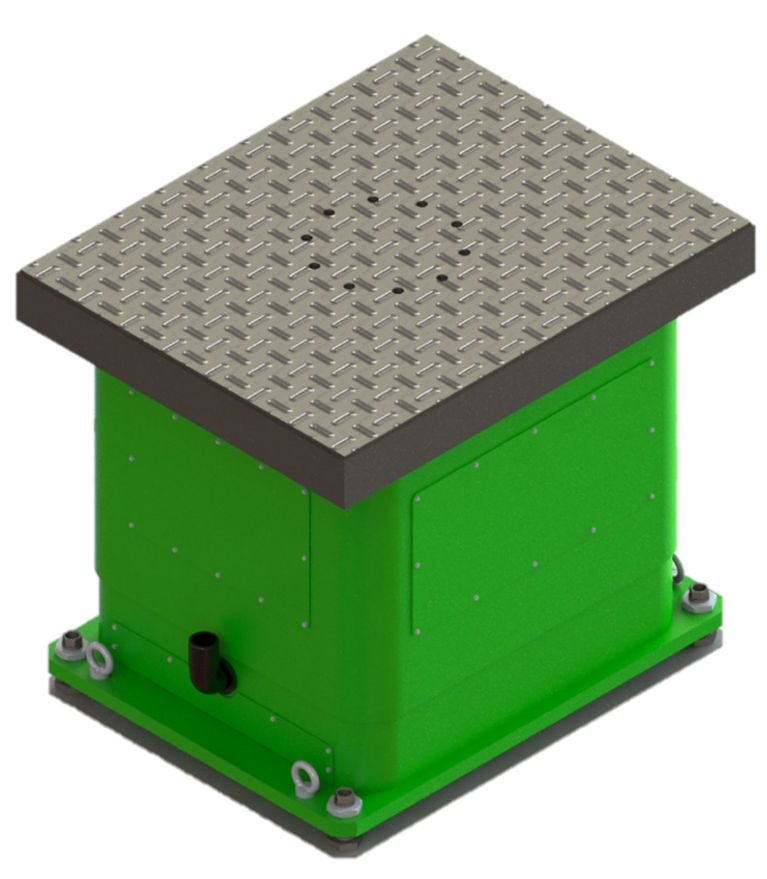

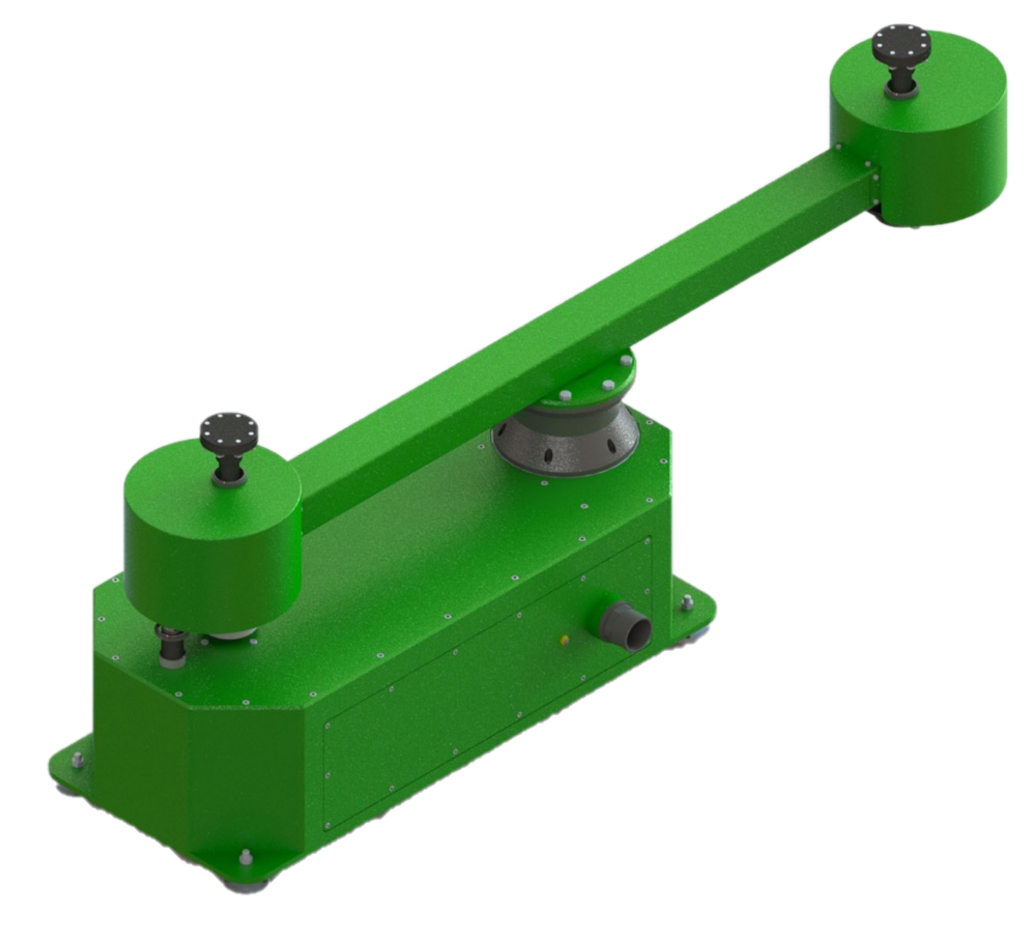

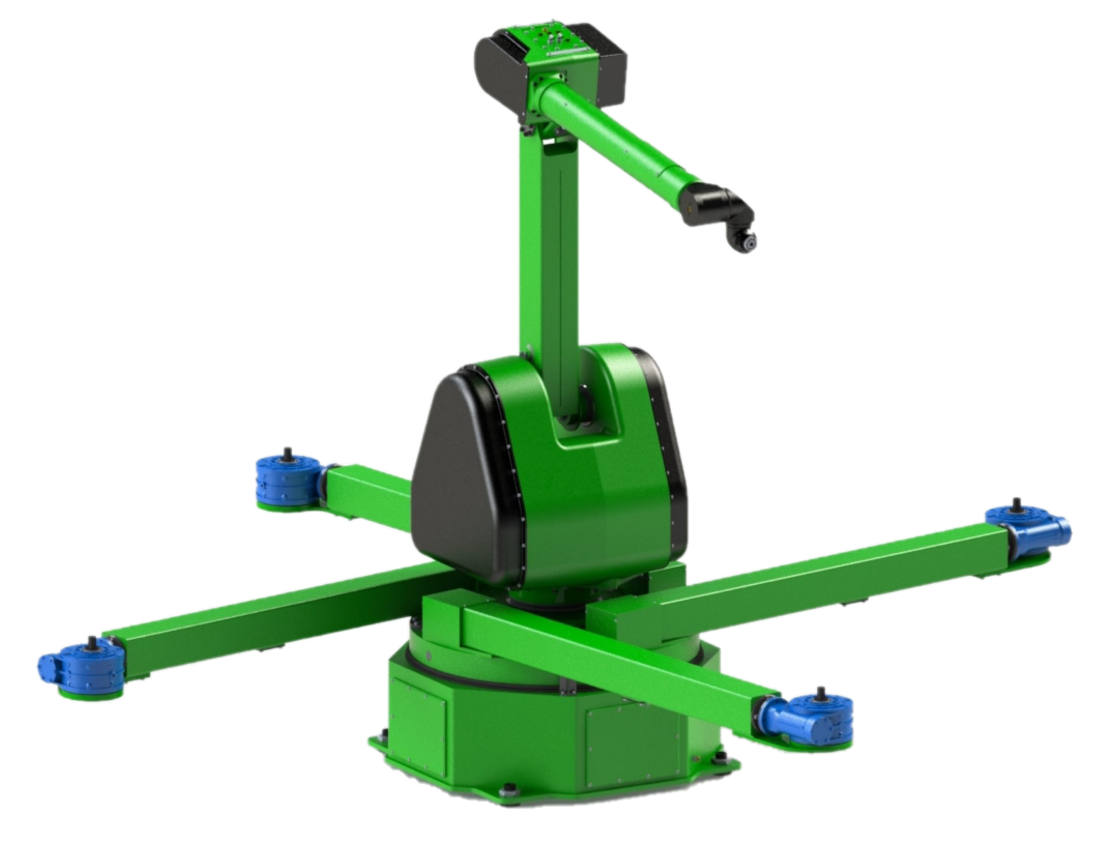

Workpiece Positioners

Designed to load and unload workpieces in a safe zone. Usually comes in a form of carousel or rotational platforms. This way, a workpiece can be painted by the robot whilst the next workpiece is loaded on, ready for painting. The rotating positioners are automatically controlled by the robot to ensure smooth and accurate synchronisation. Some examples of workpiece positioners can be seen below. Customisation to these positioners are also available to suit your products.

Fixed (Non-rotating)

Stand-alone (Rotating)

Integrated on the robot (Rotating)

We can also work with various brands of robots, such as FANUC, YASKAWA, ABB, KAWASAKI, PANASONIC, MOTOMAN, OTC, NACHI, DENSO, KUKA, MITSUBISHI, EPSON, STAUBLI, FOXCONN, COMAU, OMRON, and UNIVERSAL Robots